- Sorry, this product cannot be purchased.

Cicio Performance Diamond Claw Crank Lock (Post Crank) for R35 GT-R

Our Ultimate Solution to the metal transfer between the flywheel and crankshaft as a result of fretting. Save yourself the headache of buying a new crankshaft or flywheel in the future by getting your Cicio Performance Crank Lock Today!

Call for Price

Diamond Claw Crank Lock (Post Crank) for R35 GT-R By Cicio Performance

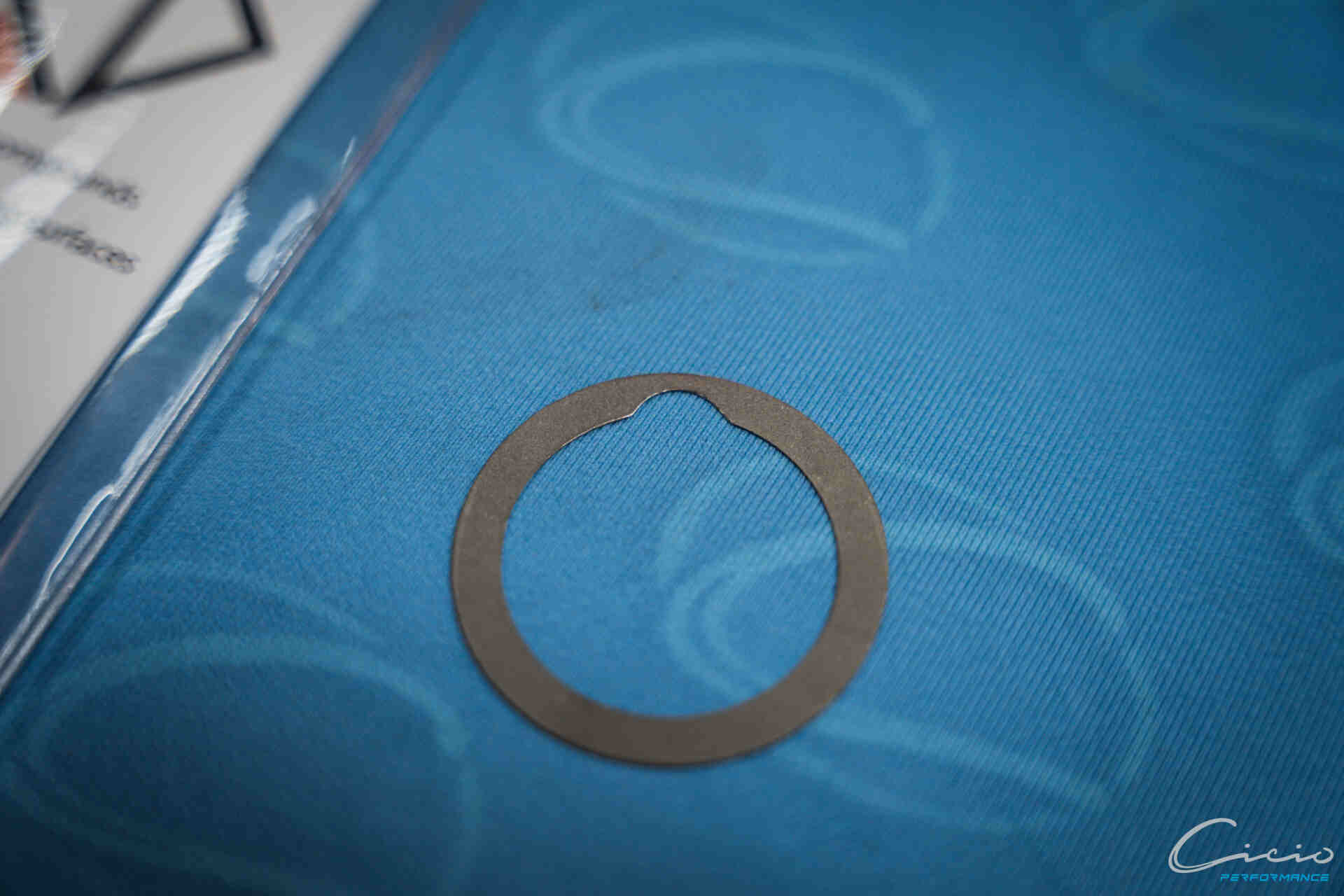

NOTE: There are two diamond claw crank locks utilized when piecing together your VR38. The Pre crank (Flywheel side with all the holes for the flywheel) and Post crank (damper side with one notch for the crank). This product is the post crank but both should be purchased together in which you can do so below. Keep reading for the full explanation.

It’s with great pleasure that we would like to introduce you a small yet powerful addition to your GT-R build. While this little part is small and inexpensive it most certainly doesn’t mean it’s not very powerful. We believe it is going to save a great deal of headache for lots of customers, engine builders and shops world wide.

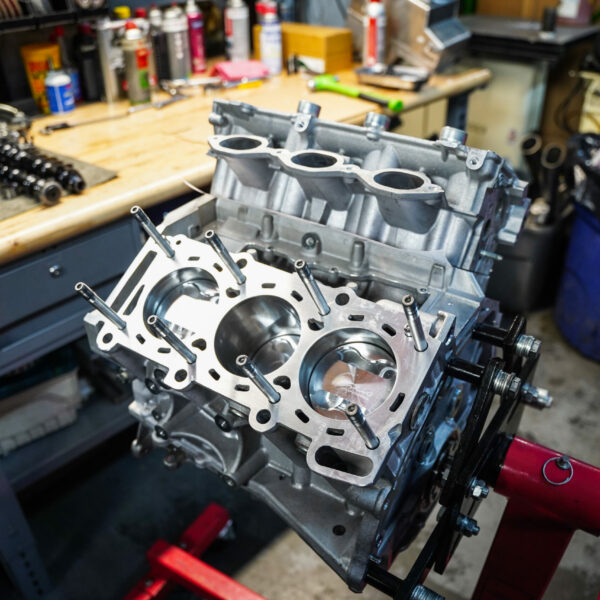

Having built just about as many GT-Rs as anybody in the world we have had plenty of opportunities to see all the little curve balls these cars can throw you when they are pushed to the limit. At the end of the day, when you take an engine designed to make 500hp and turn it to upwards of 4 times that there are both big and little battles to fight.

One of the small problems we’ve continuously seen over the years no matter what we’ve tried was metal transfer from the crank to the flywheel as a result of fretting. This is a very similar situation to friction welding, in that cause two metals are pressed into one another with relative motion creating enough heat to fuse the two. Something very similar is what happens to the two surfaces we are speaking about. With the amount of RPM and power these cars make what you eventually see is surface welding on driveline components when pulling them apart. You can see what I’m talking about in the picture of a used high HP flywheel below.

While this might not be evident to the end user at times it is a battle that every shop and engine builder undoubtedly face. Most of the time you can clean up the surface of the flywheel and the crank without any catastrophic effects, however there are times you damage a very expensive billet crank or upgraded flywheel far beyond repair.

There are items on the market that minimize this such as stronger bolts and better material flywheels. However nothing we have used came close to eliminating it….until now!

We began working closely with a company that specializes in solving just these type of problems. Our first product together focuses on the crank to flywheel mating surface as that is the biggest problem area. We will have future releases including other areas of the driveline that are currently in testing and production.

This .014” thick diamond washer is made of Cubic Boron Nitride, which in essence is man made diamond particles. It acts as a hardened locking device between the two surfaces preventing them from moving at all! Some OE manufacturers use similar type products on things like cam gears to cam surface, eliminating even the need for a dowel of any kind. Let me tell you it works!

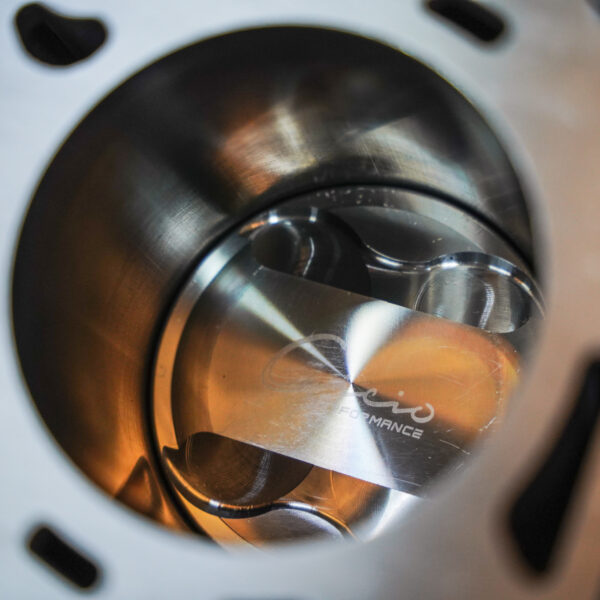

We use them on every single one of our builds now and we’ve pulled multiple bell housings after running cars over and over again at the drag strip, half mile, and street well over 1500hp. The surface of the crank looks absolutely perfect. Literally like it was never installed. Never have we seen that when pulling cars apart after they have been run hard.

Not only will you have less chance of major failure based on zero movement between your crank and the rest of your driveline, this little washer could save you thousands down the road when it’s time for a refresh.

This is a product exclusive to Cicio Performance but we are pricing them for the masses! If you are getting any type of upgraded engine GT-R built I highly recommend you buy one of these or have your shop of choice contact me for wholesale pricing. They are worth their weight in Diamonds.

- Requires no special surface preparation or applied compounds

- Minimal installed thickness does not change driveline spacing

- It protects your Crankshaft and driveline investment

- Insures interchangeability between components

- No change in driveline installation required

- Reusable for multiple installations

- Simple & easy to install

SKU NIS5304-1 Categories Cicio Products: GT-R, Engine: GT-R, Nissan GT-R Tags 2009-11 Nissan GT-R, 2012-16 Nissan GT-R, 2017+ Nissan GT-R, Cicio Performance, Nissan GT-R Drivetrain & Transmission, Nissan GT-R Engine